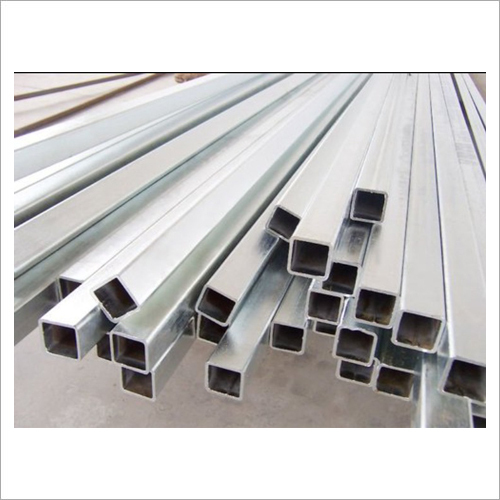

Gp Rectangular Pipe

Gp Rectangular Pipe Specification

- Coating Type

- GI (Zinc) Coating

- Tensile Strength

- 310 MPa min.

- Diameter

- N/A for rectangular pipes

- Bend Radius

- Depends on thickness; typically not designed for bending

- Temperature Range

- -20°C to 70°C

- Tolerance

- ±0.3 mm

- Connection Type

- End welded or flanged

- Yield Strength

- 310 MPa min.

- Flexibility

- Rigid

- Product Type

- GP Rectangular Pipe

- Material

- Galvanized Iron

- Connection

- Welded

- Shape

- Rectangular

- Standard

- IS 4923 / ASTM A500

- Surface Treatment

- Galvanized

- Outer Diameter

- Custom sizes available, typically 20 mm to 100 mm

- Section Shape

- Rectangular

- Length

- 6 meters (standard), custom lengths available

- Thickness

- 1.2 mm to 6 mm

- Color

- Silver

- Usage

- Construction, Infrastructure, Fabrication

- Rated Pressure

- Not rated (dependent on thickness and application)

- Application

- Structural, Mechanical, General Engineering

- Material Grade

- IS 4923 YST 310 / ASTM A500 Gr A, B, C

Gp Rectangular Pipe Trade Information

- Minimum Order Quantity

- 1 Ton

- Main Domestic Market

- All India

About Gp Rectangular Pipe

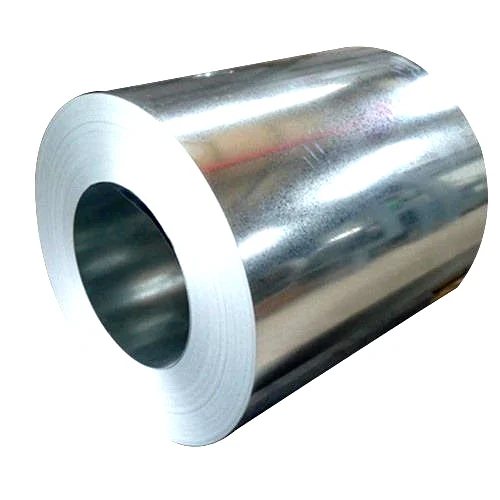

Pre Galvanized pipes are manufactured from a coil that has undergone the galvanization process .

Nezone Pre Galvanized (GP)Square,Rectangular and round pipe are manufacturerd from high Zinc coated galvanized steel coils,which are manufatured in house maintaining high quality standards and also the coating of zinc in controlled to ensure maximum resistance in corrosive environment resulting in higher life .Pre Galvanized pipes are primarily used for roofing structure,Highly effective in coastal regions & can withstands extreme humid weather conditions due to zinc coating which act as a barrier between humid weather and steel.

| Rectangular Gp Pipe | |

| Size | Thickness Range |

| 25x12 | 0.80 - 2.00 |

| 30x20 | 0.80 - 2.50 |

| 40x20 | 0.80 - 2.50 |

| 50x25 | 0.80 - 2.80 |

| 60x40 | 1.00 - 3.20 |

| 75x25 | 1.00 - 3.20 |

| 80x40 | 1.00 - 3.20 |

| 96x48 | 1.20 - 3.20 |

| 122x61 | 1.20 - 3.20 |

| 40x10 | 0.80 - 2.80 |

| 50x10 | 0.80 - 2.80 |

| 60x10 | 0.80 - 2.80 |

| 40x30 | 0.80 - 2.80 |

Specifications of GP Pipes:

- Material: High-quality galvanized steel

- Outer Diameter: 15mm to 300mm

- Thickness: 0.80mm to 6.00mm

- Length: Customizable as per requirements

- Zinc Coating: 120 GSM to 550 GSM for enhanced corrosion resistance

- Standards: IS 1239, IS 3601, IS 1161, ASTM A53, BS 1387

- End Finishing: Plain, Threaded, or Coupled

- Surface Finish: Bright, Smooth, and Uniform Zinc Coating

- Pre -coated with high zinc

- 100% Conforming to quality norms(IS:4923/IS:3601)

- HIgh tensile and yield strength ensures higher load bearing capacity

- IN house manufacturing from Hr coil >>GP Pipe assures highest quality standards

- Made from 100% Hr Coil

General Applications

-

Building Construction

-

General Engineering

-

Fabrication

-

Industrial Shed

Built for Strength and Longevity

Engineered to withstand rigorous use, these GP Rectangular Pipes boast a minimum yield and tensile strength of 310 MPa. The high-corrosion resistance from the galvanization process ensures durability even in harsh environments, making them a dependable option for long-term structural projects.

Versatility Across Multiple Applications

Suitable for construction, infrastructure, and general engineering, these pipes can be customized in both length and diameter to suit varied project specifications. Compatibility with standard steel connectors ensures seamless integration into a wide array of frameworks and assemblies.

Quality Assurance and Compliance

Manufactured as per IS 4923 and ASTM A500 standards, each batch of pipes can be supplied with a test certificate upon request. Strict tolerance controls (0.3 mm) and thorough inspection procedures underpin the consistent quality and performance of every supplied product.

FAQs of Gp Rectangular Pipe:

Q: How are GP Rectangular Pipes manufactured?

A: These pipes are produced using the Electric Resistance Welded (ERW) method and subsequently coated with a zinc layer through hot dip galvanization for enhanced corrosion resistance.Q: What makes these pipes suitable for construction and engineering applications?

A: With high tensile and yield strength (minimum 310 MPa), rigid structure, and superior corrosion resistance, these pipes are ideal for structural, mechanical, and fabrication uses, ensuring longevity and reliability.Q: When can I request a test certificate for my order?

A: Test certificates confirming mechanical and chemical properties are available upon request at the time of order placement or delivery, depending on your specific requirements.Q: Where should GP Rectangular Pipes be stored before use?

A: For best preservation, these pipes must be stored in a dry, covered area to prevent moisture exposure and maintain their galvanization integrity.Q: What benefits does the galvanization provide?

A: The hot dip galvanized coating offers high corrosion resistance, extending the lifespan of the pipe and significantly reducing maintenance needs, especially in outdoor and humid environments.Q: How can I order custom sizes or thicknesses for my projects?

A: Custom lengths and outer diameters within the specified range can be arranged as per your project needs, subject to minimum order policies. Contact the supplier or manufacturer to discuss customization options.

More Products in GP Pipes Category

Gp square pipe

Minimum Order Quantity : 10000

Usage : Construction, Fencing, Fabrication

Application : other, Structural, Industrial, domestic

Section Shape : Other, Hollow Square

Surface Treatment : Other, PreGalvanized / ElectroGalvanized

GP Pipes

Price 52 INR / Metric Ton

Minimum Order Quantity : 10000

Usage : Industrial

Application : Construction

Section Shape : Square

Surface Treatment : Galvanized

Gp Coils

Price 65 INR / Metric Ton

Minimum Order Quantity : 1000

Usage : industrial

Application : Industrial

Section Shape : Round

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS