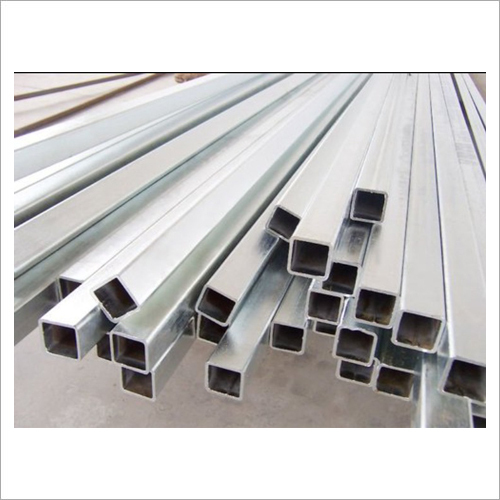

GP Pipes

Price 52 INR/ Metric Ton

GP Pipes Specification

- Features

- Good Quality

- Corrosion Resistant

- Yes

- Usage

- Industrial

- Surface Finish

- Smooth

- Application

- Construction

- Shape

- Square

- Surface Treatment

- Galvanized

- Section Shape

- Square

GP Pipes Trade Information

- Minimum Order Quantity

- 10000 Metric Ton

- Supply Ability

- 10000 Per Day

- Delivery Time

- 1 Months

- Main Domestic Market

- All India

About GP Pipes

Pre Galvanized pipes are manufactured from a coil that has undergone the galvanization process .

Nezone Pre Galvanized (GP)Square,Rectangular and round pipe are manufacturerd from high Zinc coated galvanized steel coils,which are manufatured in house maintaining high quality standards and also the coating of zinc in controlled to ensure maximum resistance in corrosive environment resulting in higher life .Pre Galvanized pipes are primarily used for roofing structure,Highly effective in coastal regions & can withstands extreme humid weather conditions due to zinc coating which act as a barrier between humid weather and steel.

why Nezone GP pipe ?

- Pre -coated with high zinc

- 100% Conforming to quality norms(IS:18573/2024)

- HIgh tensile and yield strength ensures higher load bearing capacity

- IN house manufacturing from Hr coil >>GP Pipe assures highest quality standards

- Made from 100% Hr Coil

-

GP Square pipe Size Thickness Range 15x15 0.80 - 2.00 19x19 0.80 - 2.00 20x20 0.80 - 2.00 25x25 0.80 - 2.50 30x30 0.80 - 2.50 38x38 0.80 - 2.80 40x40 0.80 - 2.80 50x50 1.00 - 3.20 60x60 1.00 - 3.20 72x72 1.20 - 3.20 100x100 1.20 - 3.20

Superior Industrial Strength

GP Pipes are crafted for demanding industrial settings, providing exceptional structural support and resilience. Their galvanized coating ensures maximum resistance to rust and wear, delivering longevity for challenging construction environments.

Precision Surface Treatment

Each pipe undergoes a high-quality galvanizing process, resulting in a smooth, uniform finish. This surface treatment not only enhances appearance but also improves the pipes anti-corrosive properties, making them suitable for long-term use in varied climates.

Versatile Square Design

The square section shape offers versatility in application, enabling easy integration in frameworks, support beams, and other structural components. This design makes installation seamless and strengthens overall construction stability.

FAQs of GP Pipes:

Q: How are GP Pipes used in industrial and construction projects?

A: GP Pipes are widely employed in industrial and construction projects as structural supports, frameworks, and conduits. Their square shape offers stability, making them ideal for applications requiring robust frameworks and reliable strength.Q: What makes these GP Pipes corrosion resistant?

A: These pipes are galvanized, which means they are coated with a protective layer of zinc. This galvanization process prevents rust and corrosion, extending the service life even in harsh or humid environments.Q: When should you choose GP Pipes with a square section?

A: Square-section GP Pipes are optimal when projects demand consistent load distribution, easy joining, and aesthetic uniformity. Their shape ensures a strong, reliable framework, particularly suited for modern construction and industrial usage.Q: Where are your GP Pipes manufactured and supplied from?

A: Our GP Pipes are manufactured, exported, and supplied from India, meeting stringent national and international quality standards to ensure reliable global delivery and customer satisfaction.Q: What is the process involved in achieving a smooth and corrosion-resistant surface finish?

A: The pipes undergo a detailed galvanizing process, where they are coated in molten zinc. This process creates a smooth, even finish and a durable barrier against corrosion, ensuring a lasting, high-quality surface.Q: What are the main benefits of using your GP Pipes for construction?

A: Key advantages include their excellent corrosion resistance, high structural strength, and uniform square design. These attributes make them dependable for challenging construction tasks, promising longevity and minimal maintenance.

More Products in GP Pipes Category

Gp square pipe

Minimum Order Quantity : 10000

Surface Treatment : Other, PreGalvanized / ElectroGalvanized

Material : Other , Galvanized Iron (GI)

Shape : Square

Application : other, Structural, Industrial, domestic

Gp Rectangular Pipe

Minimum Order Quantity : 1 Ton

Surface Treatment : Galvanized

Material : Other , Galvanized Iron

Shape : Rectangular

Application : other, Structural, Mechanical, General Engineering

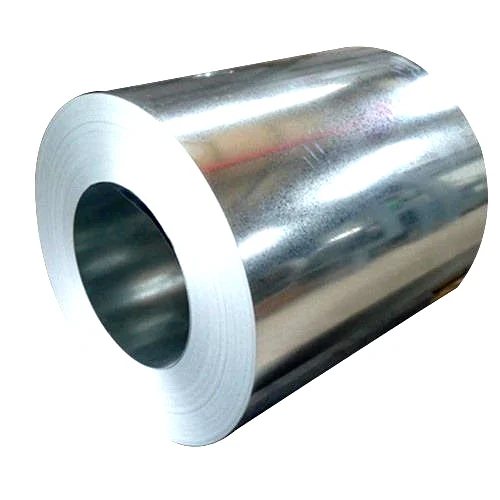

Gp Coils

Price 65 INR / Metric Ton

Minimum Order Quantity : 1000

Surface Treatment : Galvanized

Material : Iron

Shape : Round

Application : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS