Octagonal pole

Octagonal pole Specification

- Coating Type

- Hot Dip Galvanized

- Diameter

- 70mm â 180mm

- Yield Strength

- â¥250 MPa

- Tolerance

- ±3mm

- Tensile Strength

- â¥410 MPa

- Connection Type

- Flange/Anchor Bolted

- Flexibility

- Rigid

- Temperature Range

- -25°C to +60°C

- Product Type

- Octagonal Pole

- Material

- Mild Steel

- Connection

- Base Plate with Anchor Bolts

- Shape

- Octagonal

- Standard

- IS 2062 / EN 10025

- Surface Treatment

- Hot Dip Galvanized

- Outer Diameter

- 70mm â 180mm (across flats)

- Section Shape

- Octagonal

- Length

- 3m â 12m

- Thickness

- 3mm â 8mm

- Color

- Silver (Galvanized)

- Usage

- Street Lighting, High Mast Lighting

- Material Grade

- IS 2062 Gr A / S235JR

- Application

- Outdoor Illumination

About Octagonal pole

Octagonal pole

Technical Specification:

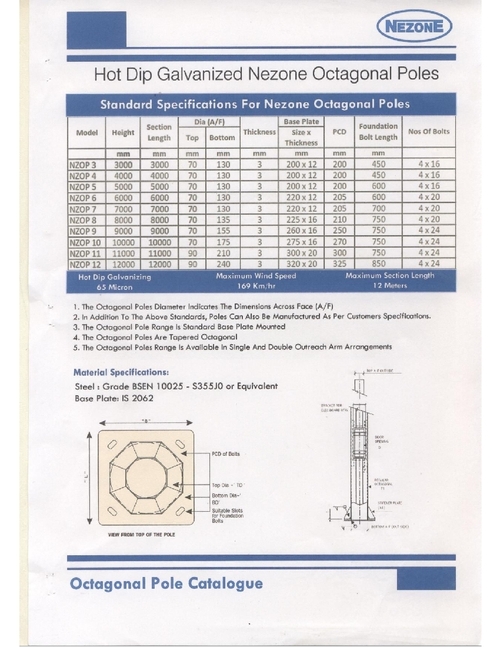

| Hot Dip Galvanized Nezone Octagonal Poles Standard Specifications For Nezone Octagonal Poles | |||||||||

| Model | Height | Section Length | Dia (A/F) | Thickness | Base Plate | PCD | Foundation Belt Length | Nos Of Bolts | |

| Top | Bottom | Size x Thickness | |||||||

|

| mm | mm | mm | mm | mm | mm | mm | mm |

|

| NZOP 3 | 3000 | 3000 | 70 | 130 | 3 | 200x12 | 200 | 450 | 4x16 |

| NZOP 4 | 4000 | 4000 | 70 | 130 | 3 | 200x12 | 200 | 450 | 4x16 |

| NZOP 5 | 5000 | 5000 | 70 | 130 | 3 | 200x12 | 200 | 600 | 4x16 |

| NZOP 6 | 6000 | 6000 | 70 | 130 | 3 | 220x12 | 205 | 600 | 4x20 |

| NZOP 7 | 7000 | 7000 | 70 | 130 | 3 | 220x12 | 205 | 700 | 4x20 |

| NZOP 8 | 8000 | 8000 | 70 | 135 | 3 | 225x16 | 210 | 750 | 4x20 |

| NZOP 9 | 9000 | 9000 | 70 | 155 | 3 | 260x16 | 250 | 750 | 4x24 |

| NZOP 10 | 10000 | 10000 | 70 | 175 | 3 | 275x16 | 270 | 750 | 4x24 |

| NZOP 11 | 11000 | 11000 | 90 | 210 | 3 | 300x20 | 300 | 750 | 4x24 |

| NZOP 12 | 12000 | 12000 | 90 | 240 | 3 | 320x20 | 325 | 850 | 4x24 |

| Hot Dip Galvanizing | Maximum Wind Speed | Maximum Section Length | |||||||

- The Octagonal Poles Diameter Indicates The Dimensions Across Face (A/C)

- In Addition To The Above Standards, Poles Can Also Be Manufactured As Per Customers Specifications.

- The Octagonal Pole Range Is Standard Base Plate Mounted

- The Octagonal Poles Are Tapered Octagonal

- The Octagonal Poles Range Is Available In Single And Double Outreach Arm Arrangements

Material Specifications:

Base Plate : IS 2062

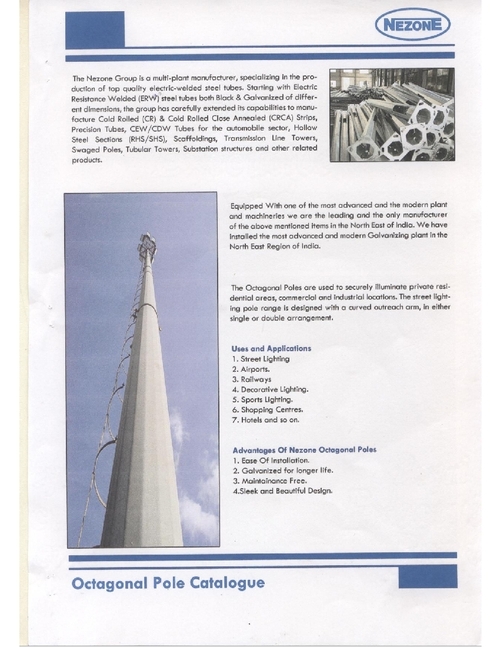

Superior Structural Performance

Engineered for resiliency, our octagonal poles feature wind resistance up to 180 km/h and are fabricated from mild steel grades IS 2062 Gr A or S235JR. Their rigid design ensures stability and safety for applications such as street and high mast lighting, even in demanding weather conditions.

Corrosion-Resistant Durability

With a hot dip galvanized surface treatment, these poles retain their structural integrity and silver finish for years, even under fluctuating temperatures from -25C to +60C. The galvanization process and compliance with RoHS and ISO 9001 standards guarantee long-lasting outdoor performance with minimal maintenance.

Tailored to Your Needs

Our poles are available in a variety of lengths, diameters, and thickness options. Customizable base plates, mounting heights up to 12 meters, and access to optional lightning protection and factory-provided earthing make these poles ideal for any outdoor illumination or infrastructure project.

FAQs of Octagonal pole:

Q: How are the octagonal poles installed and secured for outdoor use?

A: The octagonal poles are mounted using a flange or anchor bolted connection to a custom base plate, designed according to pole height and project requirements. Galvanized steel anchor bolts provide secure footing and corrosion resistance for long-term outdoor deployment.Q: What factors influence the selection of pole section and wall thickness?

A: Pole sections (single or multiple) and wall thickness, ranging from 3mm to 8mm, are chosen based on the required height, wind resistance (up to 180 km/h), and application type, ensuring structural integrity and safety as per design.Q: When should lightning protection be considered for these poles?

A: Lightning protection is optional and recommended for areas prone to thunderstorms or where critical infrastructure is illuminated. The provision ensures extra safeguarding of electrical systems against lightning-related surges.Q: Where can these poles be utilized effectively?

A: Designed for outdoor environments, these poles are ideal for street lighting, high mast lighting, and other outdoor illumination projects, especially in climates ranging from -25C to +60C.Q: What process is followed to guarantee corrosion resistance and quality?

A: Each pole undergoes hot dip galvanizing to provide a robust, corrosion-resistant surface. Manufacturing complies with IS 2062 or EN 10025 standards, while RoHS and ISO 9001 certifications underline adherence to environmental and quality regulations.Q: What are the benefits of choosing galvanized steel anchor bolts for mounting?

A: Using galvanized steel anchor bolts increases durability by preventing rust, reduces maintenance needs, and ensures the pole remains safely secured over many years of outdoor service.

More Products in Octagonal pole Category

Octagonal Galvanized Poles

Minimum Order Quantity : 1 , , Container

Color : Silver

Product Type : Other

Material : Other

Tolerance : ISO standard tolerance Meter

Tensile Strength : 355 MPa Pounds per Square Inch (psi)

9 Mtr Octagonal pole

Color : Silver/Grey (Galvanized)

Product Type : Other, Octagonal Lighting Pole

Material : Other , Mild Steel (MS)

Tolerance : ±3 mm

Tensile Strength : 410 MPa minimum

Octagonal Galvanized Poles

Minimum Order Quantity : 10 Pieces

Color : Silver

Product Type : Other, Octagonal Galvanized Poles

Material : Stainless Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS